Stand alone wire harnesses Highly individual and customized

We are an experienced partner of the automobile industry.

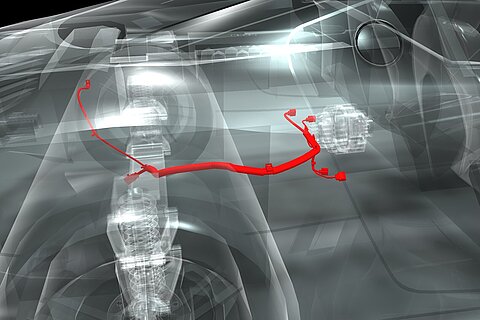

Individual customer requirements are the order of the day, especially in the case of stand alone cable harnesses. Because our cable harnesses have to fit 100 percent – and we provide customized solutions for that. This is where our pronounced process experience and flexibility are a great advantage, because we analyze possible installation options, optimize wire-routing processes and manufacture prototypes. This can only be done together and in close collaboration with customers. These abilities enable us to provide customers with short development times, continual cost optimization and process efficiency.

What our customers can expect from us:

- A wealth of experience in manufacturing cable harnesses

- Cooperation in Simultaneous Engineering Teams (SETs)

- Development-based qualification

- Preparation of wiring diagrams

- 3D cable harness routing and collision detection tests (DMU) via simulation software

- Preparation of cable harness and component diagrams

- Interfaces to customers and suppliers

- Preparation of functional models using 3D printing processes

Battery and generator cable harnesses

We employ the following specifications when we manufacture cable harnesses:

- Insulation material: high-quality materials such as silicone

- Conductor material: copper, aluminum

- Cross-section: 16 to 70 mm²

- WeWire uses crimp terminals, tubular cable lugs, and die-cast contacts such as battery clamps

Engine wiring

For engine wiring, cable harnesses with intelligently designed jacket and protective materials are required, which minimize weight and maximize reliability. We utilize:

- Sealed connection systems

- Single conductors, heat-resistant up to 200°C

- Highly flexible cables for cramped installation spaces

- Cable protection systems to support flexibility and abrasion protection

- Twisted conductors or sheathed cables for signal shielding

- Sealed potential distributors

Seat wiring

We develop and produce cable harnesses not only for seats, but also for doors, roofs, valves, air conditioners, shock absorbers, etc., with corresponding peripherals, for example with:

- Highly flexible single conductors

- Airbag wiring

- Motion compensation using braided sleeving

- Abrasion protection tape

- Specially designed fastening systems

- Cable ducts

Complete solutions, all from one supplier

The production and routing of cable harnesses involves a highly complex development process performed in close collaboration with our customers. The process can often takes some time until the stand alone cable harness is finally installed in a series vehicle: from the pre-development order, to 3D routing and all the way to test phases in prototype vehicles.

At WeWire, we have the distinct advantage of being able to rely on the experience and expertise of our Coroplast Group during the entire process. For example, special-purpose tapes from Coroplast Tape, which exactly meet the protective requirements of the application, can be suggested and developed in-house with a minimum of lead time. Coroflex can also provide us with customized cables and wiring, such as for high-temperature FEP conductors or silicone conductors with heat-resistant capabilities up to 200°C.

Your contact person Cable harness systems