Coroplast Global | Insights Digital transformation at Coroplast

A pragmatic approach to the digital future

We at Coroplast face the same challenges as many other businesses which, over a period of several decades, have gone from being a small, family-managed company to a group with worldwide operations and several thousand employees. And we, too, are under pressure to adapt processes which used to be optimally aligned to the needs of our organisation and its customers to this new situation. “Coroplast is a success story. If a brand is strong enough, timely optimisation often tends to remain unnoticed. We pay particular attention to improving our working environment and making it fit for the future. We aim to encourage learning effects through ‘agile projects’ and in doing so make the transformation ‘fit’ on a people level”, says Joachim von der Bey.

70 % of all transformation projects fail because they are unable to get the people most directly affected on board.

The “digital for future” agenda

Against this background, we put together a made-to-measure digital agenda that is precisely focused on our requirements and our corporate culture: the slogan “digital for future” reflects our pragmatic approach to the digital future. Over the next few years we will be guided by a roadmap with 5 key priorities:

- “Sustainable IT” refers to infrastructure and security measures as well as to the ongoing professionalisation of basic services like the IT Helpdesk for our employees.

- “Process optimisation” is concerned with the development of workflow-based business processes and with getting the most out of the leading SAP system by continuously improving and upgrading our IT landscape.

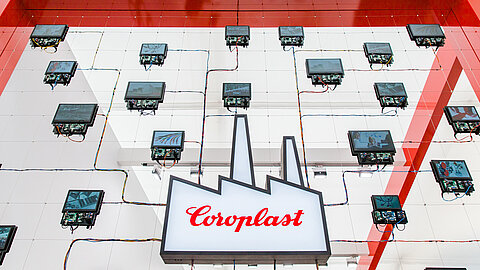

- “Smart factories” puts the emphasis on production (shopfloor management) and production control (manufacturing execution systems, MES) as well as on artificial intelligence.

- “New ways of working” places collaboration and cultural aspects on the agenda along with Coroplast as a strong employer brand. The onboarding process and digital access for all production employees are two examples that spring to mind here.

- “Digital shared services (DTS)” focuses on the ongoing development of our system landscape.

Digital transformation and the Digital Shared Services department (DTS)

Digital transformation – as we understand it – doesn’t mean technology, social media or apps; it means the transformation of processes and the way we work together. The principal challenges here are getting people on board and continuing to develop the digital system landscape at Coroplast. This is the job of DTS. “Seventy percent of all transformation projects fail because they are unable to get the people most directly affected on board. Yet the reason why Coroplast is so successful is that in the past we’ve avoided the temptation to follow every single trend blindly; instead, digitalisation has always been linked to a goal – to a specific benefit”, says digitalisation expert Joachim von der Bey.

DTS drives process optimisations, innovations and new ideas in support of the Coroplast Group’s strategies and objectives. Digital transformation is not an end in itself, but a partner and a platform for successful implementation. “We see DTS here in the role of our customers’ attorney – as a networker and a mediator that accompanies the changes taking place within our organisation. Our aim is to think strategically, and with a strong operational orientation to assist in the transition from decades-old processes to new process routines.”